Twine

Although Catahoula Manufacturing makes many products, our main product is twisted seine twine. Catahoula Manufacturing has the capability of producing over 5 million pounds of twine per year.

Making twisted twine is basically a two-step process. The first step being to twist the yarn together into one strand of the string, the first twist is then put "three-up" on the second twist machine, and then three strands are twisted into a three strand twine. At CMI we put the full amount of twist into all our twine to get a full body twine.

After the second twist, most twine manufacturers spool the twine and send it on its way. However, we take the twine to a conditioning oven where it is heat set or stabilized to minimize untwisting when the twine is cut.

After the twine is heat-set, it is taken to our tubing department where it is tubed for the consumer, the industrial user or cordage distributor.

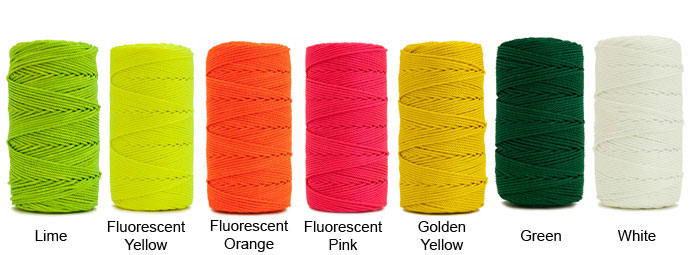

Much of Catahoula's twine is tarred or dyed before ending up in the wrapping department, where it is labeled, shrink wrapped and boxed.